Measuring air flow and pressure of a ventilating system

In ALMES Laboratory is possible to characterize aeraulic performance of fan, or ventilating system. This measurement is done by a room air ducting (also called double chamber) made in accordance with the standards specification AMCA 210/07 and ISO 5801/07.

The purpose of the test is to determine the maximum pressure (static, dynamic and total) which can reach the air flow, and the maximum amount of air moved by the fan.

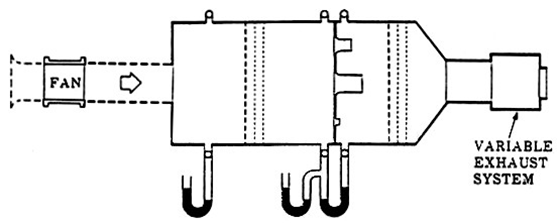

The aeraulic chamber made specifically for the ALMES Laboratory, follows the construction scheme imposed by the legislation AMCA (Air Movement and Control Association). Are provided two chambers, connected to each other, a fan of compensation and various sensors of pressure, temperature, atmospheric conditions. The two chambers contain the perforated metal inserts, which are intended to straighten the air direction and are separated from each other by a wall with six nozzles with a different diameter. The compensation fan, instead manages the exhaust system, regulating the density of the air within the second chamber. Opening or closing the nozzles suitably present in the partition wall between the two chambers, it induces an instantaneous change of the static pressure and air flow. The system then takes care record the reading of each gauge and to calculate the values that determine the curve of pressure / flow rate (curve P / Q) that will be generated later in a special report.

The maximum air flow is measured in the condition of absence of static pressure, created in the second chamber from the variable exhaust system. The difference in air pressure between the first and the second chamber is measured with the fan running and the nozzles open.

The maximum static pressure is measured with the fan running and the nozzles completely closed. This allows you to have the first chamber is completely sealed so as to be able to detect the maximum value of static pressure. The value of static pressure is the difference between the maximum pressure generated in the first chamber and the atmospheric pressure.

The measurements are done with the motor hot and when the fan speed reaches a point of stability, at voltage rating.

With ALMES aeraulic chamber, you can capture the following data:

- Airflow

- Static pressure

- Dynamic pressure

- Total pressure

- Power and current absorbed by the motor

- Power output

- Efficiency of the system

- Speed of the impeller

- Environmental conditions